Mold Design

- Home

- Capabilities

- Mold Design

1. Get Your Plastic Part Design Fast

2. Evaluate All Of Design Considerations For Injection Molding

Plastic Parts Evaluation

After we get initial design from you, we extract information to evaluate the feasibility of every design element.

DFM

We integrate Design for Manufacturability throughout the product development process to facilitate production, reduce costs and eliminate potentially expensive delays.

Mold Design Adjustments

Our designers can make recommendations including material selection, wall thickness analysis, tooling, mold flow analysis, surface finish and part decoration based on our expertise.

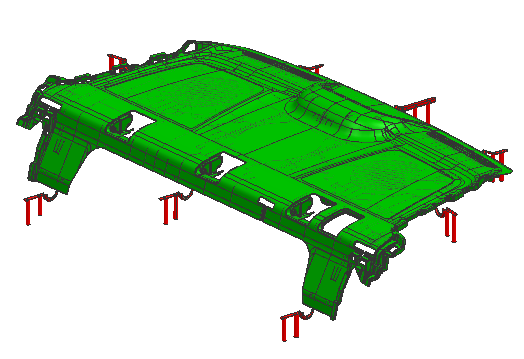

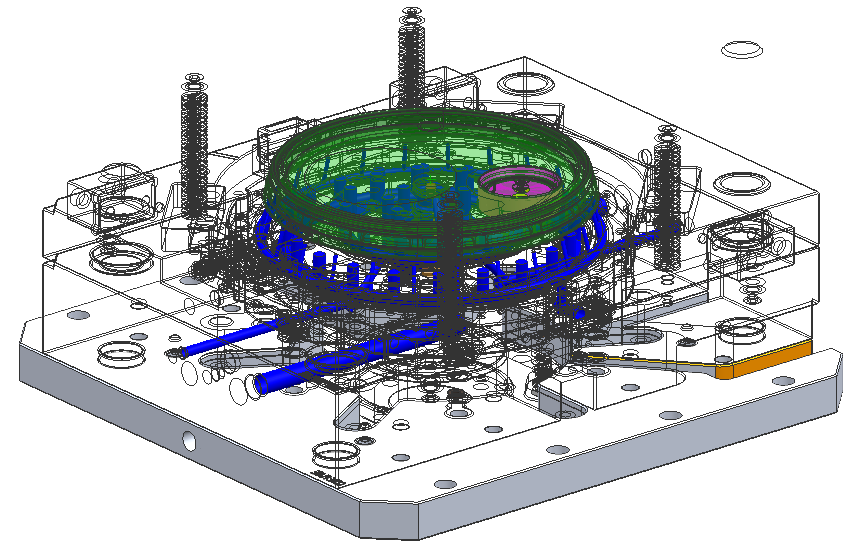

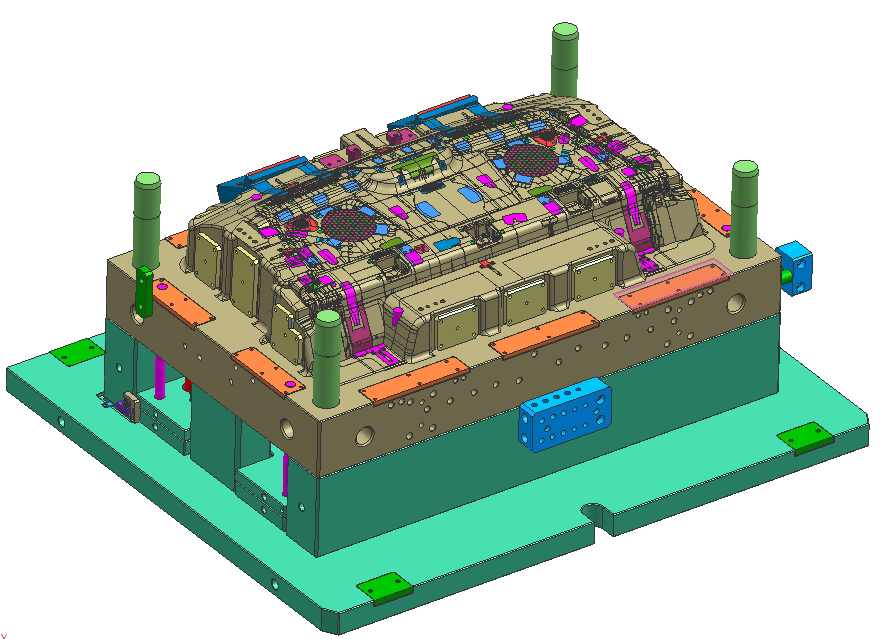

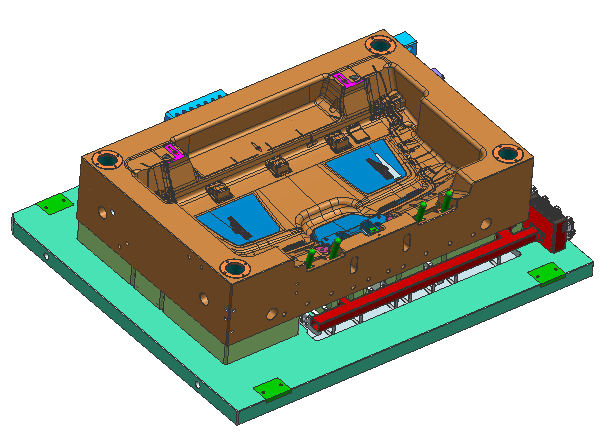

3. Various Plastic Injection Tooling Design We Made

Overmold

The Overmold method is a plastic injection technique that seamlessly combines several materials into a single component. This technique gives the manufacturer more control over their product, and add a stylish finish as well.

Insert Mold

This form of molding is more varied, and involves the insertion of a metal part into a mold, before the actual instance of injection molding. Once the insertion is finished the mold is closed, and plastic is molded over the insert to transform it into a single component.

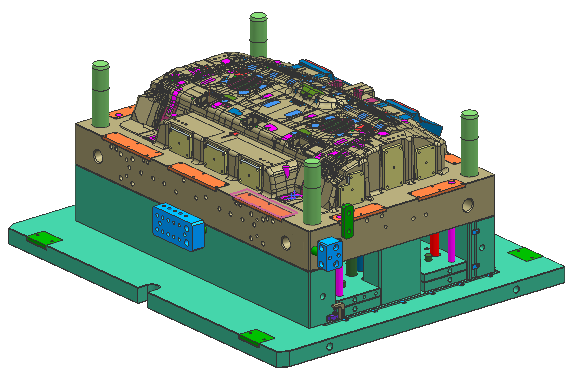

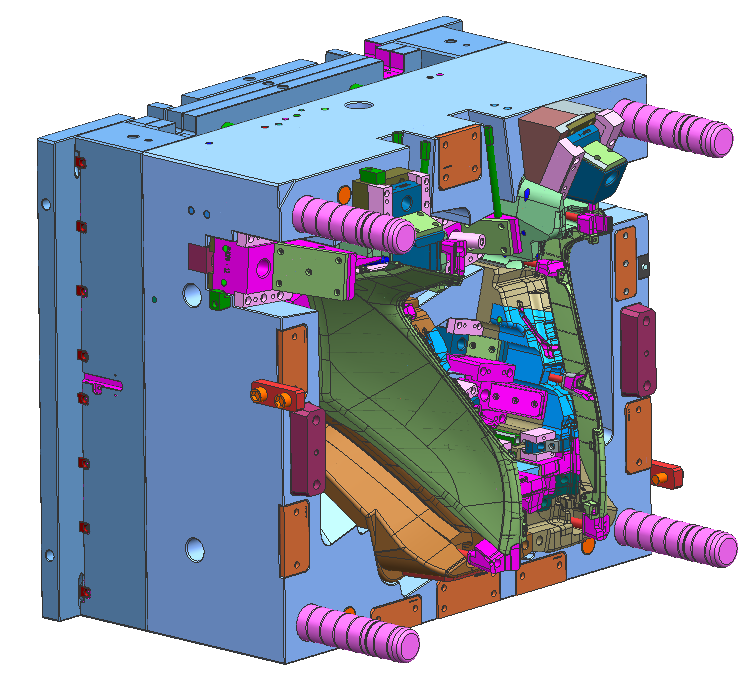

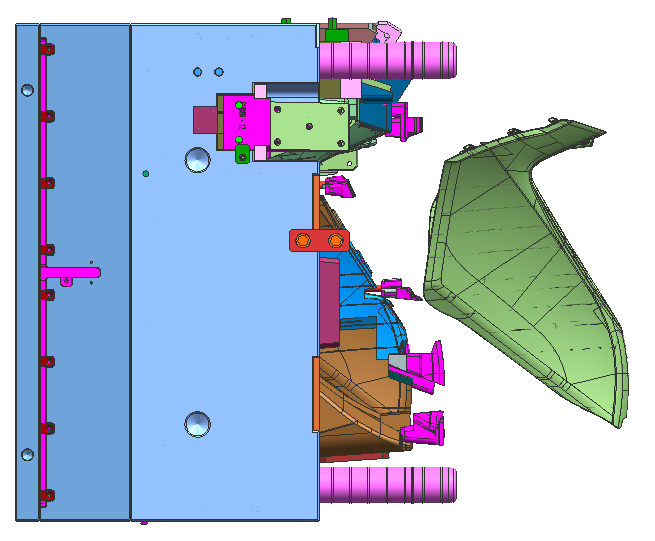

Plastic Injection Mold

Plastic injection molding is the process of directly injecting liquid plastic into the cavities of a specially made mold. This is the key service of Sun High-Tech, and we have complete manufacturing facilities from CNC, EDM, Wire Cutting, Milling, Drilling all located in one roof.

Design Injection Mold in Only 3 Steps

Step 1

Send Us Your Mold Sketch or Sample

Before we could start making your mold prototype, we will need a comprehensive sketch of your mold. We will use it as the core design for your plastic mold design.

Step 2

Confirm The Injection Molded Part Specifications

Once we have your design specifications, we will need you to confirm them. We will consider a green light to create your mold.

Step 3

Confirm DFM Analysis Report

We will conduct a DFM analysis report to ensure that the product is optimized for your project. We will need you to confirm the analysis report before we begin with mold making process.

Why Custom Plastic Injection Mold Design

with Sun High-Tech

Sun High-Tech thrives on the challenges of high-volume injection molding to produce quality parts at a mutually beneficial price. We give our customers added value through our flexible production options, durable, long-lasting molds, and expert insight. By setting our aim on creating the most reliable and efficient plastic molds possible, we can save customers even more time and money.

24/7 Communication

You will have 24/7 communication with our customer support team. They will ensure that you are given around the clock assistance and help you throughout the process.

Fast Quote

If you are interested in getting a quote for our services, you won’t have to wait long. We could give you a quote within a day.

Free Design Revision

If you have any complaints about the molding quality, Sun High-Tech is more than willing to give you a free design review. We always believe that our clients deserve the best.

Professional Mold Analysis

Before we release any molding designs, we will have our mold designers conduct a professional mold analysis. This will ensure that your molds are in the best condition possible.

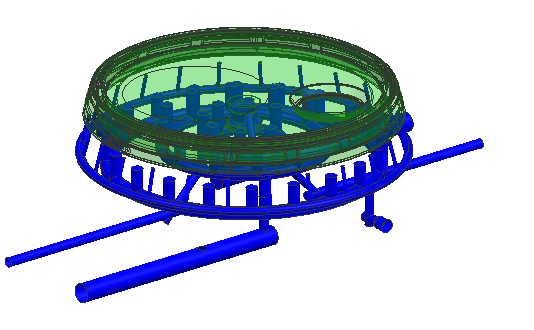

Injection Mold Designs

Injection mold gate design

Injection mold cooling system design

Injection molding system design

Ejection system design

Plastic Injection Mold Designers With Over 10+ Years’ Experience Standing By

The Sun High-Tech staff team is made up of high-skilled professionals that are quite talented. Our injection mold designers, in particular, are continuously researching and developing innovative ways to produce high-performing molds. Additionally, our factory is equipped with superior machinery to optimize all design processes.

Your feedback and satisfaction are important to us. Subsequently, our designers will seek your team’s input throughout the design process and keep you informed on progress. We also accommodate any custom plastic molding ideas or requests that you may have.